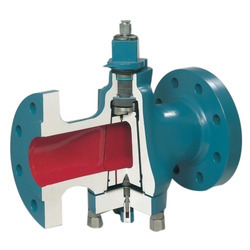

Plug valves are also known as cocks. They have cylindrical as well as tapered discs. They are generally used for full flow service as gate valves and where quick shutoff is required. They are not generally designed for flow regulation except when specially designed plugs are used e.g. for gas flow throttling.

The tapered plug tends to jam and requires a high operating torque: this is overcome to some extent by the use of a low-friction (Teflon etc.) seat, or by lubrication (with the drawback that the conveyed fluid is contaminated). The friction problem can also be solved by a mechanism which raises the disc from the seat before rotating it, or by using the eccentric design.

Construction

When opening in the tapered plug gets aligned with the direction of pipe, full flow is obtained. Flow terminates when plug is rotated quarter turn. To achieve maximum flow efficiency, careful design of valve internal counters is essential. Ports are generally rectangular, but circular ports are also available. Available valve patterns or types are regular, venturi, short, round-port. Mostly plug is tapered downward but upward tapered plugs are also available.

Topy Entry : Most of the plug valves are top entry. In top-entry plug valves, the tapered plug is installed from the top of the valve.

Bottom Entry : When plug is tapered upwards and is installed from the bottom opening in the valve body.

Cylindrical Plugs : Provide for larger port openings equal to or greater than the pipe flow area. The regular pattern employs the tapered form of port openings, the area of which is from 70 to 100 percent of the internal pipe area. In some cases, the face to-face lengths are greater than those of standard gate valves.

Venturi Pattern : Streamlined flow and reduction in the port size. The port opening area : 40 to 50 percent of the internal pipe area. In most of the plug valves, the port opening varies from 60 to 70 percent of the pipe area.

Round Port Full Bore : Operating efficiency is equal to or greater than that of gate valves.

Multiport Valves : Provide simplification of piping and convenience in operation. One three-way or four-way multiport valve may be used in place of two, three, or four straightway valves.

[google-square-ad]

|  | |

| Lubricated plug valve consists of a cavity in the middle of plug along its axis. …Read More.. | ||

|  | |

| Double block and bleed plug valve (also known as double isolation plug valve) has two …Read More.. | ||

Non-Lubricated Plug Valves

Non lubricated plug valves contain an elastomeric body liner or a sleeve, which is installed in the body cavity. The tapered and polished plug acts like a wedge and presses the sleeve against the body. Thus, the non-metallic sleeve reduces the friction between the plug and the body. Nonlubricating plug valves are used where maintenance must be kept to a minimum. Like lubricating plug valves, these valves also provide a bubble-tight closure and are of compact size.

Advantages

- Simple design with few parts.

- Quick to open or close.

- Can be serviced in place.

- Offers minimal resistance to flow.

- Provides reliable bubble tight leak proof on-off service.

- The wiping-off action of a plug does not permit suspended particles to accumulate and form crud.

- Seal can be maintained by injection of sealant or by replacement of sleeve, in addition to utilizing the wedging action of a tapered plug.

- Multiple port design helps reduce number of valves needed and permits change in flow direction.

Disadvantages

- Requires greater force to actuate due to high friction.

- NPS 4 (DN 100) and larger valves require use of actuators.

- Reduced port, due to tapered plug.

- Typically, plug valves may cost more than ball valves.

Applications

- Air, gaseous, and vapor services

- Natural gas piping systems

- Coal slurries, mineral ores, mud, and sewage applications

- Oil piping systems

- Vacuum to high-pressure applications

Sample Material Specifications

Service : Sour Hydrocarbons, Sour Gas etc.

- Size : 2 to 6”

- ELEMENT: Plug Valve

- Ends : Flanged Ends Raised Face STANDARD: B16.10

- Type : Full Bore,

- MATERIAL: ASTM A216 Gr. WCB NACE, Max C.E.,

- Heat Treatment : Post Weld Heat Treatment

- CLASS: 150

- ENDS: Raised Face

- OPERATION: Lever Operated

- TRIM: Plug 316 / PTFE Sleeve

- See Data Sheet

Service : Liquid Sulphur.

- Size : 2 to 6”

- ELEMENT: Plug Valve

- Construction : Short pattern jacketed

- Ends : Flanged Ends Raised Face STANDARD: B16.10

- Type : Full Bore,

- MATERIAL: ASTM A216 Gr. WCB

- Heat Treatment : Post Weld Heat Treatment

- CLASS: 150

- ENDS: Raised Face

- OPERATION: Lever Operated

- TRIM: Plug CS / PTFE Sleeve

- See Data Sheet

[google-square-ad]

Photos

[jdpostimage imagesrc=”https://www.pipingengineer.org/wp-content/uploads/plug-valves-01.jpg” imagecaption=”Plug Valve”][jdpostimage imagesrc=”https://www.pipingengineer.org/wp-content/uploads/plug-valves-02.jpg” imagecaption=”Plug Valve”]