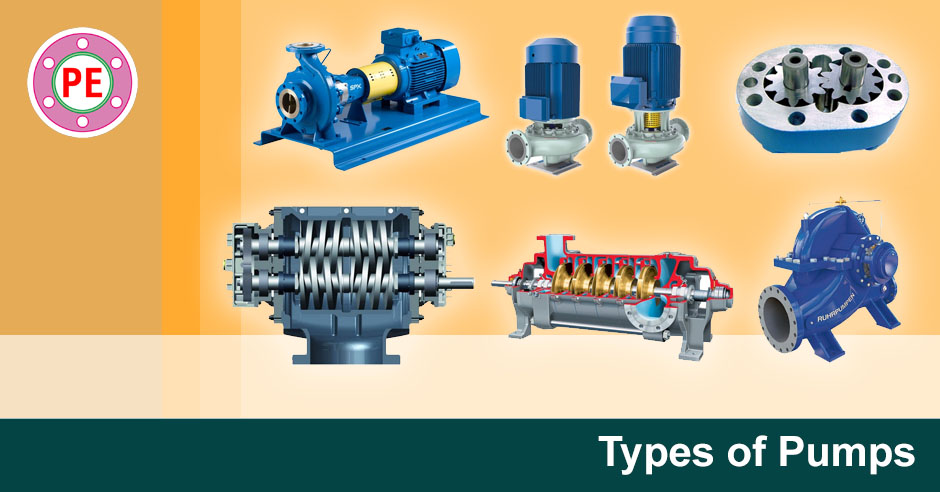

This article lists out various types of Pumps used in a refinery and a chemical plant. These pumps are classified as centrifugal, positive displacement (reciprocating), or rotary.

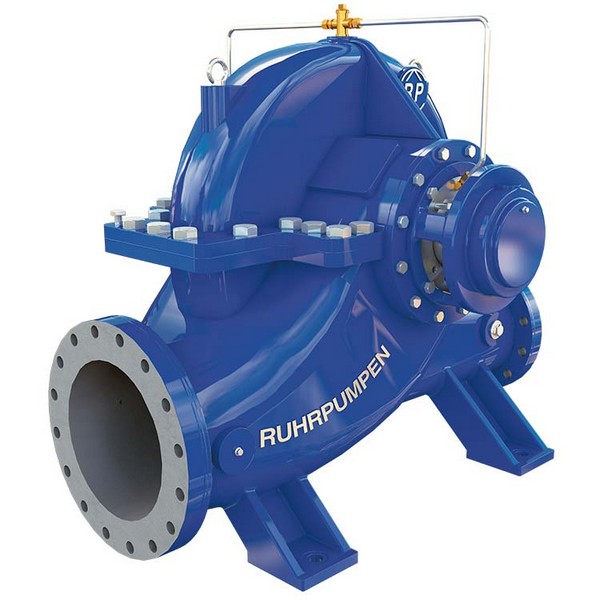

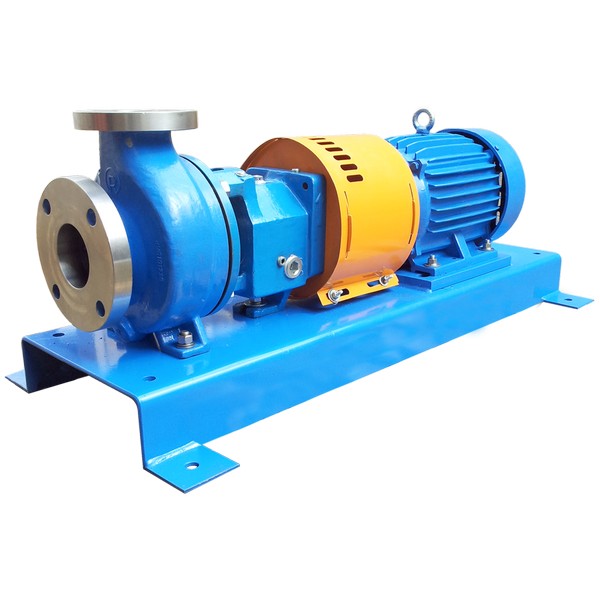

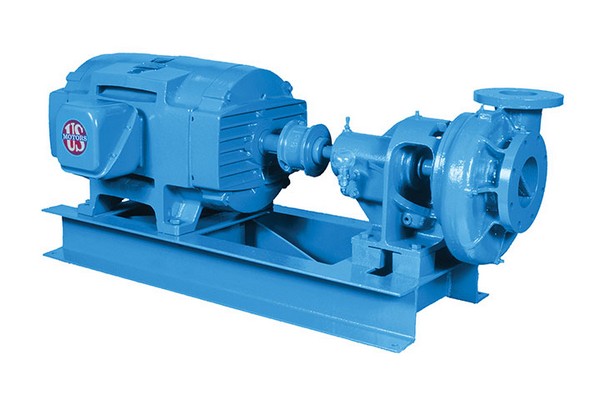

Centrifugal Pumps

The majority of pumps used in industry are centrifugal because of their flexibility in flow rates, pressure, and temperature.

They are usually driven by electric motors or steam turbines.

They may be single stage or multistage, depending on pressure requirements in the system, and can be horizontal or vertical.

Centrifugal pumps, unlike reciprocating and rotary pumps, operate at constant speed and it can deliver any capacity from zero to maximum, depending on the head design and suction conditions.

Following drawing depicts some of the more common variations of centrifugal pumps.

Horizontal Split Case Pump

Chemical Process Pump (ANSI Pump)

Multistage High Pressure Pump

Horizontal – Frame Mounted Pump

Inline Process Pump

Vertical Sump Pump

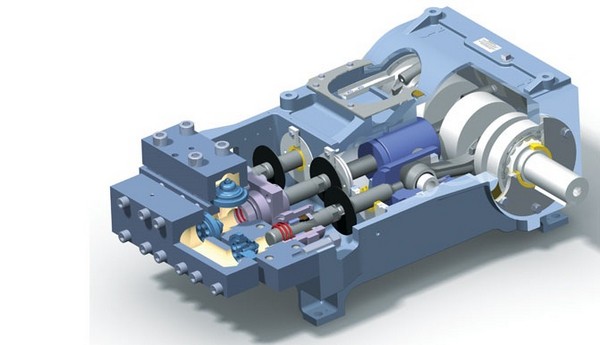

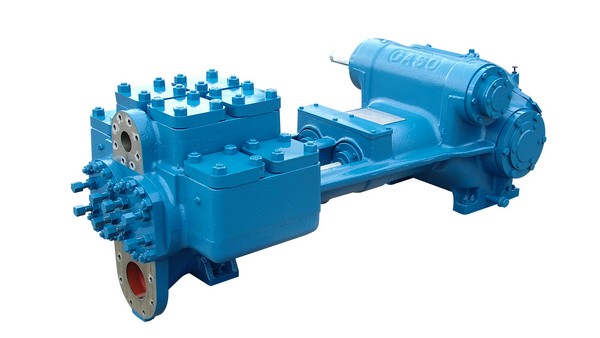

Positive Displacement (Reciprocating) Pumps

These pumps are commonly used to move viscous liquids, inject chemicals or additives into a system, or pump quantities too small for centrifual pumps.

These pumps discharge a definite quantity of liquid during piston or plunger movement through the stroke distance.

Following drawing shows two typical reciprocating pumps.

Single Acting Plunger Pump

(For very high pressure with moderate flows and high efficiency)

Double Acting Piston Pump

(For viscous liquids and slurry service)

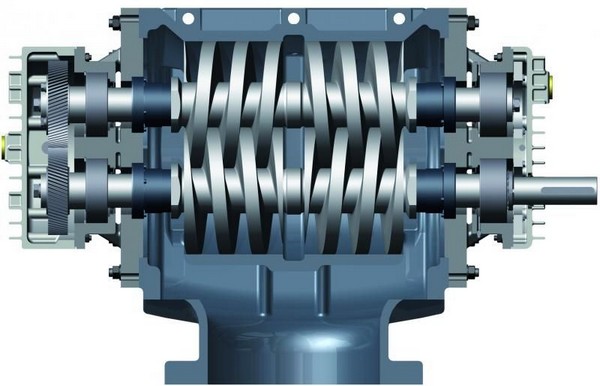

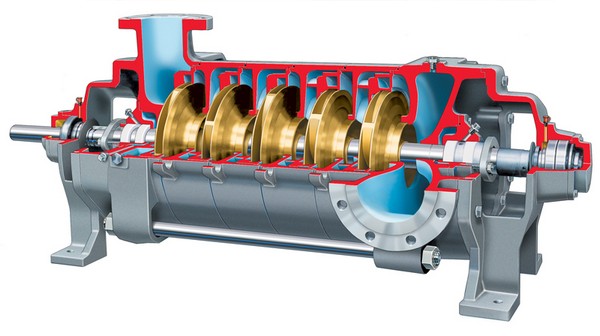

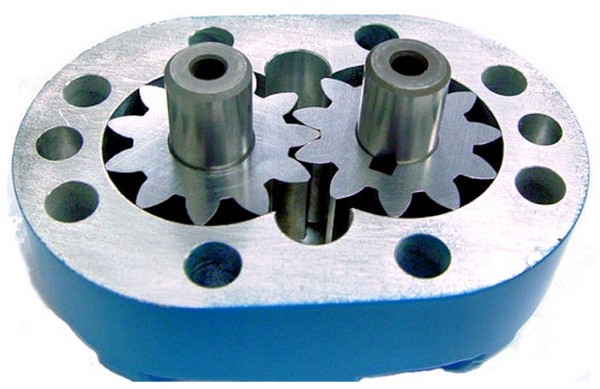

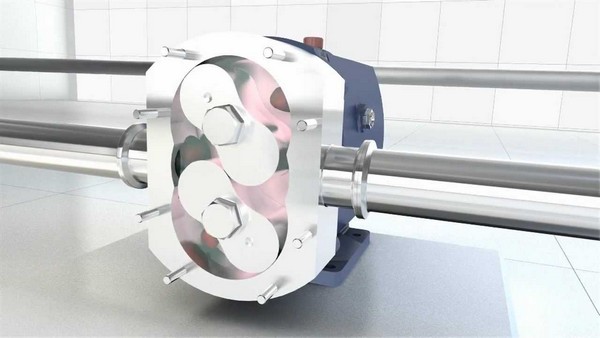

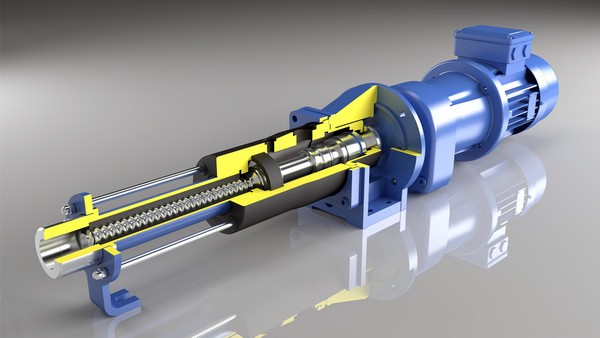

Rotary Pumps

These pumps are generally used for viscous liquids that are free of hard and abrasive solids.

Rotary pumps push the liquid within the casing; by gears, vanes, and cams. The liquid is then discharged in a smooth flow, unlike with the reciprocating, pump.

These pumps are also characterized by the absence of suction and discharge valves. One advantage of rotary pumps is their ability to send out a constant volume against variable discharge pressures.

Some variations of rotary pump design are illustrated below.

External Gear Pump

Two-Lobe Pump

Three-Lobe Pump

Single Screw Pump

Two-Screw Pump