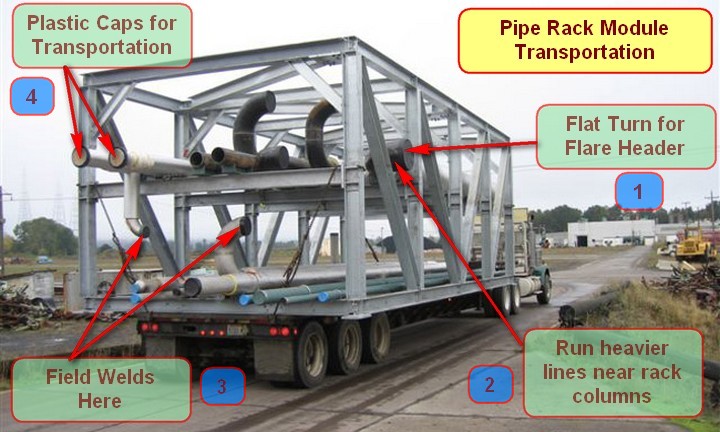

Note 1 : Flare headers have flat turn in and out of rack to avoid liquid pocket as well as slope requirements.

Note 2 : Try to run heavier lines near the pipe rack columns so that minimum moment load comes on columns.

Note 3 : Modular pipe rack construction requires field welding of pipe ends.

Note 4 : Plastic caps are provided at pipe ends to avoid damage to pipe internals from dust and moisture or any other foreign matter, during transportation.