Function of instrumentation in a process plant is to gather intelligence from the operating plant, and control the process as per predefined conditions. It mainly measures various process conditions such as pressure, temperature, flow, density and level. By doing so, it keeps them under control as per process requirements.

Responsibilities of us as piping engineering people regarding process instrumentation includes modelling of these instruments in 3D model at proper locations from where they can be easily accessed and maintained. Also it is necessary to take into consideration any process requirements of a concerned instrument.

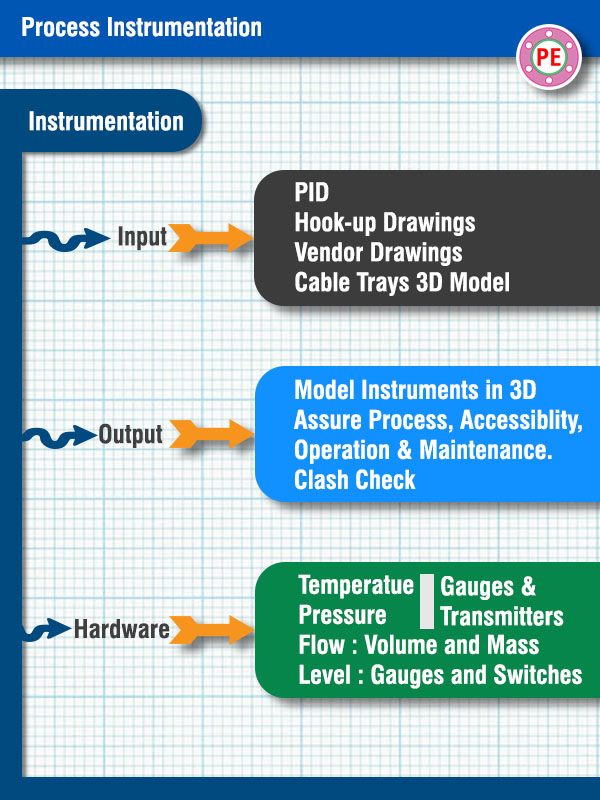

We have to use inputs from Process as well as Instrumentation department along with general layout practices to locate these instruments properly in 3D Model/Piping Layout. The inputs that we have to refer are as follows :

PID from process department.

A piping guy should properly check out PID legend sheet to correctly understand type of instrument in a given process line. Also it is essential to read any notes associated with particular instruments in PID.

Instrument Hook Up Drawings from Instrumentation Department.

These drawings provide information about how a particular instrument is to be connected to piping and its interface piping components, type of connection, type of valves required etc. These drawings also provides information on maintenance requirements, straight flow requirements, access requirements. They also include demarcation of supply scope of piping and instrumentation departments. Standard assemblies can be made in 3D software used on the project, so that they can be easily and consistently placed in model.

[google-square-ad]

Piping Design Basis

This is our internal department document customized for particular project we work on. It specifies guidelines regarding placement of instruments on various equipments from maintenance, process and operation point of view. These guidelines must be piously adhered to.

Co-Ordination With Instrumentation Department

Instrumentation department provides instrumentation hook up drawings, straight length requirements for flow meters, control valve data sheets / drawings. They also provide us with dimensional drawings of various instruments like Level gauges, flow meters, control valves, density meters etc.

3D modelling by instrumentation department includes instrumentation related ducting, and other accessories, panels etc. It is necessary to clear all clashes with these ducting in co-operation with instrumentation department. Instrumentation department review piping 3D models for correct placement of Instrumentation, to ensure satisfaction of process, operation and maintenance requirements.

I have put together brief introductions to various instruments used in process industry. Check out the links below. Your comments and suggestions are highly welcomed.

| Measuring temperature of a fluid in pipe and vessels is achieved by installing local temperature …Read More.. |

| Pressure measurement is a critical function in Process Control. It is measured locally or via …Read More.. |

| Level measurement of fluids in process equipment is necessary to maintain proper fluid levels in …Read More.. |

| Maintaining proper flow of fluids in a process system is essential to maintain correct supply …Read More.. |

| Control of flow of process and utility streams is achieved with the help of a …Read More.. |

[google-square-ad]