When client gives welding contract to a welding contractor, that welding Contractor shall appoint agency for carrying out the radiography works at site from the list of agencies enclosed in the bid document or separately supplied by client.

The Radiographic Examination procedures to be adopted shall be submitted by the contractor in format specified by client and shall be got approved from the Owner’s Inspector prior to employment. A person qualified to ASNT Level-II or ASNT Level-III in Radiographic testing shall prepare the procedure. The Radiography Procedure shall be established to demonstrate that the required sensitivity can be consistently achieved under the most unfavorable parameters (e.g. source to film distance, geometric unsharpness, thickness etc.).

The radiographic technique and procedure adopted shall conform of the requirements mentioned in Article 2 as well as Article 22 of ASME Sec.V. The IQI sensitivity obtained shall be equal to or better than the requirements mentioned in Article 2 of ASME Sec.V. Source side penetrameter shall be used in establishing radiographic procedure/ technique. The acceptance criteria shall be as per

the relevant codes of Fabrication and over riding requirements if mentioned else where in the technical specifications of the contract.

The Contractor shall be responsible for carrying out Radiography; rectification of defects and re-radiography of welds repaired/rectified at his cost.

The extent of Radiography shall be as per specifications to be supplied to the Contractor. For welds between dissimilar materials, the extent of Radiographic Examination shall be the more stringent of the two recommended for the materials being welded. Wherever random Radiography is called for, in a particular piping class, the dissimilar materials weld joints shall essentially be included.

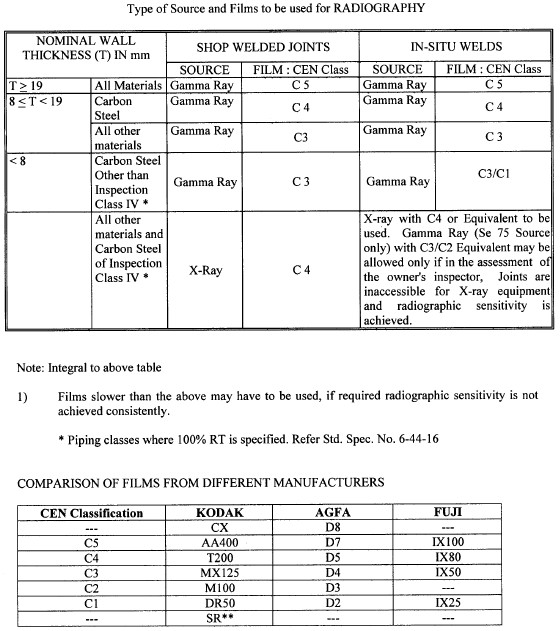

Type of Radiation source and film to be used shall be as show below for carrying out radiographic examination. However if specifications (as given else where in the contract) for some critical material require usage of X-Radiation, then Radiography shall be done using X-Rays only.

The Contractor shall fulfill all the statutory and owner’s safety requirements while handling X-ray and Gamma-ray equipments.

In case of random radiography, the joints for Radiography shall be selected by the Owner’s Inspector and the Radiography shall be performed in his presence, if he instructs the contractor to do so.

The contractor shall furnish all the radiographs, to the Owner’s Inspector immediately after processing along with evaluation by a person qualified to ASNT Level-II in Radiographic testing, inline with Article 2 of ASME Sec.V. The certificate of ASNT/ISNT Level II qualification of the NDT personnel shall be submitted to owner’s inspector for his approval prior to start of job.

The Contractor shall provide the Owner’s Inspector, all the necessary facilities at site such as a dark room with controlled temperature, illuminator (viewer) suitable for varying densities, a duly calibrated electronic densitometer with batteries, magnifying

glass, tracing papers, ruler, marking pencils etc. to enable him to review the radiographs.

Where random radiography is specified, the first weld of each welder shall be completely radiographed. In the case of pipe of size 6″ and below, the first two welds shall be completely radiographed.

For each weld performed by a welder found unacceptable, two additional checks shall be carried out on welds performed by the same welder. This operation is iterative and the of two additional welds for each weld deemed unsatisfactory shall be continued till

such time that two consecutive welds of satisfactory quality are found for every defective weld.

The Contractor shall carry out these additional radiographic testing at his own expense. To avoid the possibility of too many defective welds by a single welder remaining undetected for a long period to time, the Contractor shall promptly arrange for Radiographic Examination so that there is no accumulation of defective joints.

Contractor shall quote rates for X-ray as well as Gamma Ray for joints indicated to be radiographed by X-ray in Table of shown above.

Check shots

Owner I Engineer- in- charge or his representative shall select 5% of the total joints radiographed on a day for check shots. Contractor shall carry out check shots as directed.

Weld profiles of check shots shall be compared with weld profile observed in the earlier Radiographs. In the event of any one variation in the check shots and earlier Radiographs, contractor shall re-shoot the entire lot of joints radiographed by particular Radiography agency on the particular date. All the re-shot films shall be compared with the originally submitted films.