Purchase order for Flanges include Bill of Material as well as Technical Requirements for Flanges. Sample Technical Requirements for a particular project is as shown below:

Applicable Codes and Standards

All items, their dimensions, tolerances, chemical composition, physical properties, heat treatment and testing etc. shall conform to the codes and standards specified in the requisition. Deviations, if any, shall be clearly highlighted on a separate sheet by the vendor in the quotation itself.

Test Reports

- Test reports shall be supplied for all mandatory tests as per the relevant material specifications.

- Test reports shall also be furnished for any supplementary tests as specified in the requisition.

- Material test certificates (physical property, chemical composition & heat treatment report) shall also be furnished for the flanges supplied.

Flange Ends

- Ends of weld neck flanges shall be bevelled to suit the schedule / thickness of matching pipe, as specified in the requisition.

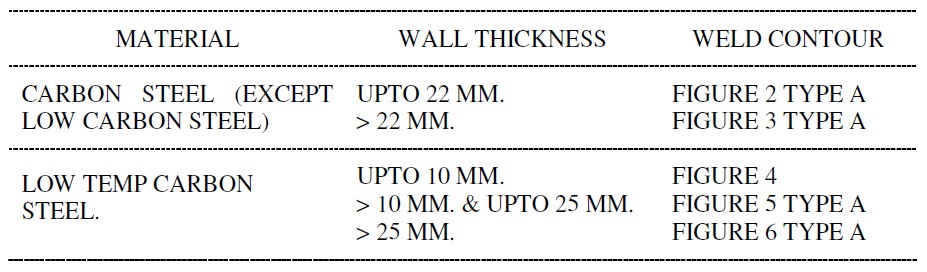

- Bevel end details for welding neck flanges shall be as per ASME B16.25. Contour of bevel end shall be as follows:

[google-square-ad]

Bore

- Bore of socket weld flanges & reducing blind flanges shall suit the outside diameter and schedule / thickness of matching pipe.

- Bore of slip on flanges shall suit the outside diameter of matching pipe.

Flange Finish

Flange face finish shall be normally specified in the requisition as serrated finish, 125 μInch AARH etc. the interpretation for range of face finish shall be as follows:

- Serrated Finish : serrations with 125 to 250 μInch AARH

- Smooth Finish : serrations with 63 to 125 μInch AARH

Threaded Flanges

- Threaded galvanised flanges shall be supplied with threads free of galvanising.

- Galvanising shall be hot dip galvanising to ASME A153/A123

- Ends of screwed flanges unless otherwise specified shall have taper threads as per ASME B 2.1 (up to 1.5 in NB.) & IS: 554. (For 2 in to 6 in. NB.)

Material of Construction

The carbon content of all carbon steel and impact tested carbon steel flanges shall be limited to a maximum of 0.25%.

Marking and Despatch

- Stamping : All items shall be legibly and conspicuously stamped in accordance with the requirements of applicable ASME, API and MSS standards.

- Marking : Paint or ink for marking shall not contain any harmful metal or metal salts such as zinc, lead or copper which cause corrosive attack on heating.

- Cleanliness : All items shall be dry, clean and free from moisture, dirt and loose foreign materials of any kind.

- Protection : All items shall be protected from rust, corrosion and mechanical damage during transportation, shipment and storage. Rust preventive on machined surfaces to be welded shall be easily removable with a petroleum solvent, and the same shall not be harmful to welding. Each end of flange shall be protected with the following materials:

- Flange face : wood, metal or plastic cover

- Bevelled end : wood, metal or plastic cover

- Threaded end : plastic plug

- Socket welding end : plastic cover or plug

- Marking on Package : Each size of flanges, blinds etc. shall be supplied in separate packaging’s marked with the purchase order no. item code no., material specification, size and rating.

[google-square-ad]