Level measurement of fluids in process equipment is necessary to maintain proper fluid levels in concerned equipment. Every equipment has Normal liquid levels (NLL), high liquid level (HLL) and low liquid level (LLL). Equipment shall ideally operate at Normal liquid level. Level sensors provide signal to pumps control unit and control valves so that they can take necessary action to maintain liquid level at NLL.

There are various types of level measuring instruments. Some are for local readout, some transmit level information to process control room. Level switches send signal only when level in an equipment goes above HLL or below LLL.

Magneto Restrictive Level Transmitter

This type of level transmitter includes a sensor wire, connected to a piezoceramic sensor inside the transmitter. This sensor wire runs straight down the sensor tube and is attached to the tension fixture at the bottom of the sensor tube.Sensor tube passes through a hole in a float. This float consists of circular magnets and moves up and down the sensor tube while floating on the liquid surface.

To find the elevation of the float and thus the level of liquid, the transmitter sends a short current pulse down the sensor wire. This pulse sets up a temporary magnetic field along its entire length. A timing circuit is triggered ON at the same time.

This magnetic field created pulse of electric current interacts with the magnetic field of permanent magnets inside the float and a torsional force is generated in the wire much like ultrasonic vibration or wave and travels back to the piezoceramic sensor at a particular speed. When the sensor detects the torsional wave, it produces an electrical signal that notifies the timing circuit that the wave has arrived and stops the timing circuit. The timing circuit measures the time interval (TOF) between the start of the current pulse and the wave’s arrival. From this information, the float’s location is very precisely determined and presented as a level signal by the transmitter. Key advantages of this technology are that the signal speed is known and constant with process variables such as temperature and pressure, and the signal is not affected by foam, beam divergence, or false echoes. Another benefit is that the only moving part is the float that rides up and down with the fluid’s surface.

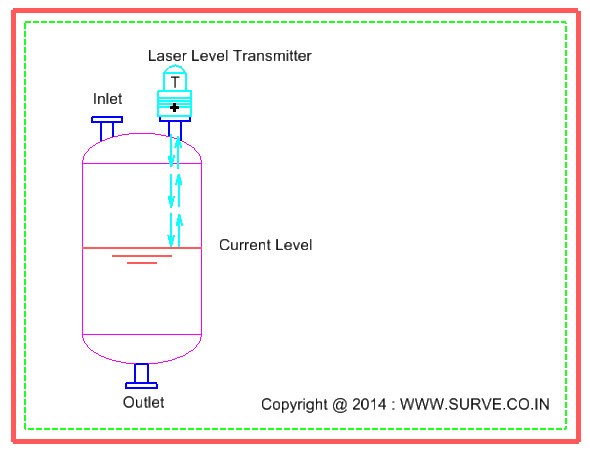

Laser Level Transmitter

Laser level transmitters use the speed of light to measure the level of liquid. A laser transmitter at the vessel top fires a short pulse of laser light down to the liquid surface which then gets reflected back to the detector in the same assembly. A timing circuit measures the elapsed time and calculates the distance. In case of high temperature or pressure conditions such as Reactors, a special sight glass window is used to contain the process conditions and separate the transmitter from process. Sight glass should be able to pass the laser beam without diffusion and attenuation.

Advantages

- lasers have virtually no beam spread (0.2° beam divergence) and no false echoes, and can be directed through spaces as small as 2 in.2

- Laser give precise readings, even in vapor and foam.

- They are ideal for use in vessels with numerous obstructions and can measure distances up to 1500 ft.

Applications

- Bulk solids

- Slurries

- Opaque liquids such as dirty sumps, milk, and liquid styrene.

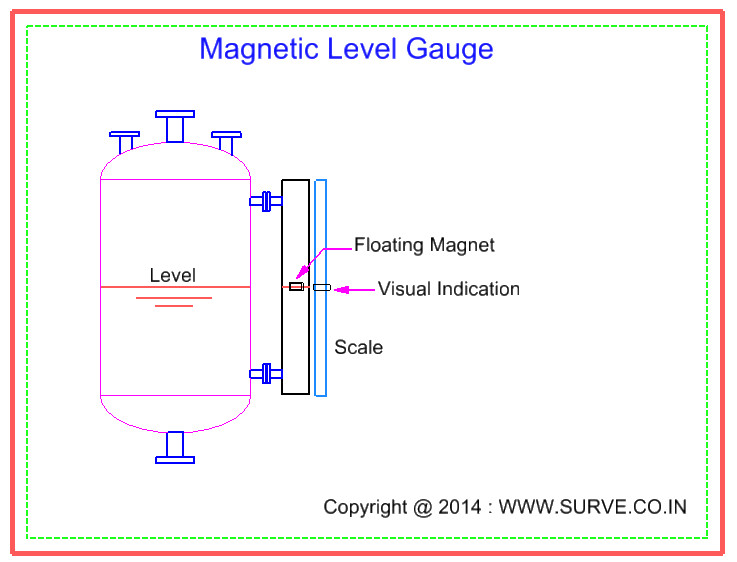

Magnetic Level Gauge

Magnetic level gauge consists of a float, carrying a set of strong permanent magnets, riding in an external tube (Float Chamber) attached to the vessel by two nozzles.

As the float moves up and down along with liquid level, a magnetized shuttle or bar graph indication moves with it, indicating the position of the float and thus providing the level indication.

Auxiliary column and chamber walls are made of non-magnetic material, mostly exotic materials like Hastelloy C-276 or engineered plastics.

Advantages

- Float designs can be optimized for the specific gravity of the fluid being measured, whether butane, propane, oil, acid, water, or interfaces between two fluids, as well as a large selection of float materials.

- They can handle high temperatures, high pressures, and corrosive fluids.

- Oversized float chambers and high-buoyancy floats are available for applications where buildup is anticipated.

- Steam jacketing can be used for Liquid Asphalt.

- Oversizes chambers can be used for Flashing conditions.

- Cryogenic temperature designs can be used for liquid nitrogen and refrigerants.

- Titanium, Incoloy, and Monel are available for varying combinations of high-temperature, high-pressure, low-specific-gravity, and corrosive-fluid applications.

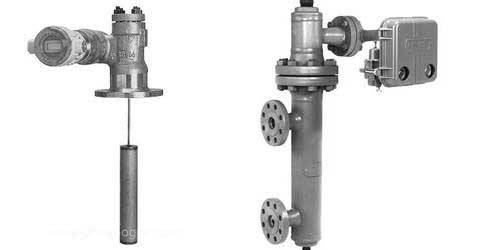

Displacement Level Measurement

This device works on the “Archimede’s Principle”. It consists of a displacer rod suspended in the vessel. Height of this displacer should be at least from lowest level to be measured to the highest level to be measured.

As the fluid level rises, displacer displaces a volume of liquid equal to the cross section of the displacer multiplied by height of displacer immersed in fluid. This displaced fluid exerts a buoyancy force on the displacer which is measured by a force transducer at the top of the displacer. Transducer is linked to the transmitter. This force is directly proportional to the level of liquid inside the tank.

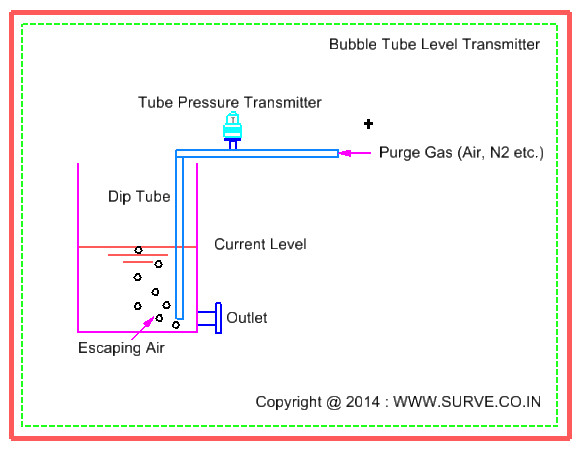

Bubble Tube Level Transmitter

A bubble tube level instrument consists of a dip tube installed in a tank. This tube has its open end near the bottom of the tank. A purge gas like Air or Nitrogen is fed to this tube. As the gas flows down the tubes outlet, pressure in the tube changes based on level of liquid in the tank as the gas has to overcome hydrostatic pressure of liquid to escape through the bottom of the tube. This pressure is measured by a pressure transducer attached to the tube. It equals the density of liquid multiplied by depth of liquid from top level to end of tube at the bottom.

Nitrogen is used instead of air when nature of liquid is such that it is necessary to avoid oxidation reactions due to air.

Aplications

Used in pressure vessels operating under atmospheric pressure.

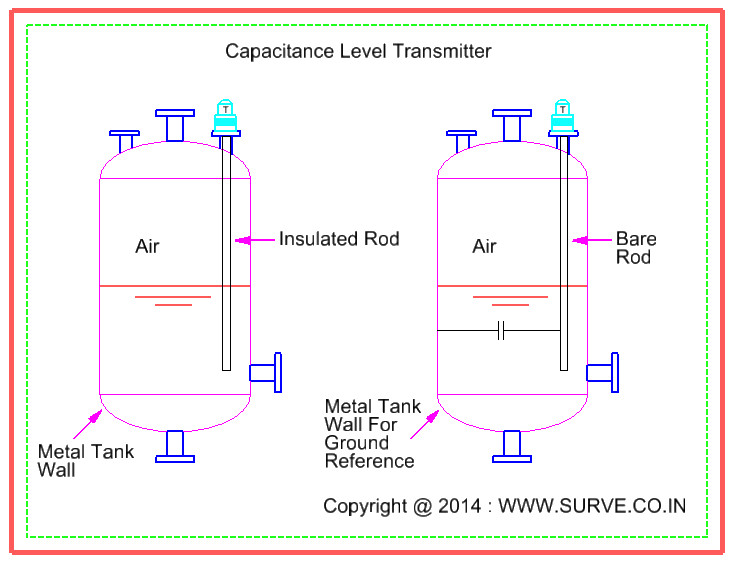

Capacitance Level Transmitter

This level measurement works on the principal of dielectric constant. Dielectric Constant of process fluids like Oils, Water Solutions etc are different from that of the Air. Dielectric constant of Air is almost 1.0.

Capacitance level sensor measures the changing capacitance between two plates, separated by process fluid.

As the fluid level rises, capacitance rises proportionally. An electric circuit called Capacitance Bridge measures the total capacitance and provides a continuous level measurement.

There are two configurations of such level transmitters :

- Capacitance is measured between process fluid and insulated rod attached to the transmitter.

- Capacitance is measure between tank metal wall or reference probe and un-insulated rod attached to the transmitter.

Nucleonic Level Transmitter

Nucleonic (gamma) level technology can be used for measuring levels of liquids as well as solids. They have been used for more than 35 Years.

It consists of a gamma source, gamma detector and a microprocessor to process the signal to human readable form. A gamma source is mounted on vessel wall without any nozzle penetration in wall as required in all other types of instruments. Gamma waves can pass through the metal wall of the vessel. Detector is installed on the opposite side of the vessel. Gamma radiation passes through the wall, some of it gets blocked by liquid or solids in the vessel and rest passes through to the receiver. Strength of detected radiation gives direct indication of level of fluid in the vessel.

As this instrument is mounted external to the vessel, it can be maintained without disturbing the process. There is risk of radiation to the personnel which can be eliminated by access restriction to the area where radiation is present during operation of the instrument.

Advantages

- They can be used for both Solids or Liquid Measurement

- Level Measurement Not Affected by: Internal Obstructions. i.e. Agitators, Extreme Process Temperatures, Caustic Processes, Violent Product Flow, Sterile Process, Changing Process, Variable Product Flow.

- Automatic Compensation for Vapor Density Changes.

- Automatic Compensation for Foam or Gasses.

- Automatic Compensation for Process Build-Up.

- Detectors Contoured to the Shape of Vessels.

Notes

- Any errors caused by changes in gas density can be eliminated by using extra “Point Detector”. With an auto calibration feature, effects of build-up on vessel walls can be eliminated.

- Previously, Geiger-Müller Tubes or Ion Chambers were used for detection of radiation, which were less efficient and high energy level source was required for proper functioning.

- New detector technology includes Scintillation Materials such as Sodium Iodide (NaI), and Plastic (PVT) crystals which have disadvantage of being rigid, heavy and are limited to individual lengths of 15 ft.

- New lightweight flexbile detectors utilizing either scintillating fill-fluid or fiber-optic bundles encased in liquid tight armoured sheathing have been invented. They enable detector to be contoured around horizontal or spherical vessels or parts of the vessels where space is limited and also ensure complete coverage over the desired measurement range.

- Typically, the measurement is repeatable to a process density of +/-0.005 SpG and ½ inch (13 mm) level.

Radar Level Transmitter

Radar level transmitter use microwaves to measure the level of fluid in a process tank. It beams microwaves downwards towards bottom of the tank. When microwaves hit the surface of the liquid, some of them get reflected back to the receiver built in the transmitter module. Time taken to travel to the liquid surface and back is measured by an electronic timing circuit.

Amount of microwaves reflected back depends on the die-electric constant of the fluid. If dielectric constant is low, less microwaves are reflected and measuring liquid level can be difficult. Water has high dielectric constant of 80, hence reflects microwaves excellently.

Horn type radar level instrument transmits microwaves through the air/vapors inside the tank. These microwaves can get reflected through the vessel internals, deposits on vessel internal parts etc. and complex fuzzy logic needs to be implemented to correctly measure the level.

Solution to above problem is Guided Wave Radar (GWR) transmitters. They incorporate a rigid or flexible cable antenna system to guide the microwaves down to the vessel. False echos from vessel walls and other parts are avoided. They are 20 times more efficient than through air radar systems due to focussed energy transmission, and can be used to measure level of liquids having dielectric constants down to 1.4 or lower.

Speed of radar waves are unaffected by vapor space gas composition, temperature or pressure. So they need no recalibration for vacuum or foams.

Ultrasonic Level Transmitter

This device uses Ultrasonic sound waves to measure the level of a liquid. It consists of a transducer which emits ultrasonic sound waves in frequencies tens of kilohertz range. This sound wave travels down to the surface of liquid and reflects back. Time required for return journey is used to measure level of liquid.

The speed of sound (340 m/s in air at 15°C (1115 fps at 60°F) depends on the mixture of gases in the headspace and their temperature. Sensor temperature is compensated for (assuming that the sensor is at the same temperature as the air in the headspace). This method is mostly used in atmospheric pressure measurements in air or nitrogen.

Float Type Level Switches

Float type level switches consists of a float displacer in a chamber. This chamber has two nozzle connections to the vessel. Liquid flows through the lower nozzle to the chamber. Changing level of float inside the chamber is sensed by a sensor inside the transmitter.

The size of nozzle connections range from 1″ to 2″. A block valve is installed between vessel and chamber so that this instrument can be maintained without disturbing the process.

Another type of level control instrument is based on an internal ball, which is generally used in vessels containing viscous liquids. Unlike the housed displacer, the ball or float is immersed directly inside the vessel through a flanged connection, which is large enough for the assembly to be withdrawn for maintenance. These instruments have no block valve and are installed on the side or on the top of the vessel.