Proper compressor layout In a process plant is essential for ideal operation, maintenance and construction requirements. compressors are used to compress gases to high pressures. This is achieved by mechanically reducing volume of gas withing case of a compressor. High pressures are required for various reasons such as particular chemical reaction requirements, or to condense the gas such as LPG, LNG etc. Variety of compressors are used based on type of gas to be compressed, pressure requirements, economy and availability.

Air is most frequently compressed, but natural gas, oxygen and nitrogen are also compressed.

Positive-Displacement, Centrifugal and Axial Compressors are the three most common types used in process facilities and pipeline stations. They can handle large volumes of gas in relatively small equipment and may have a variety of drives (e.g. electric motors and steam or gas turbines).

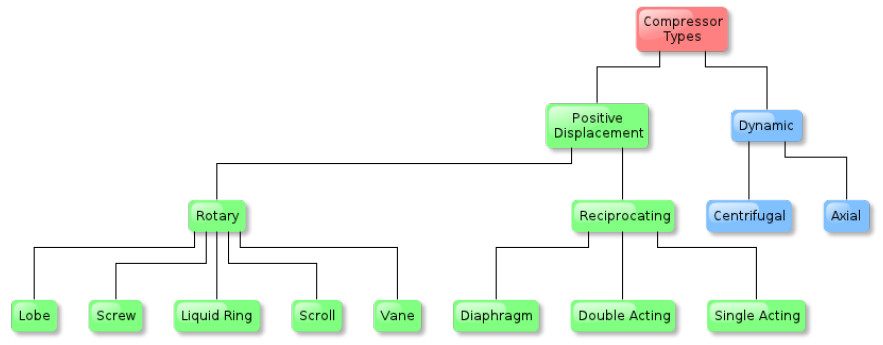

Types of Compressors

Following types of compressors are used in process plants:

|  | |

| Reciprocating compressors are usually of the reciprocating piston type and are only compressors that can compress …Read More.. | ||

Compressor Drives

Most widely used drives for compressors are electric motors, steam turbines and gas turbines. Of these, electric motors are simplest type of drive from layout point of view.

Compressor Auxiliary Equipments

Centrifugal and reciprocating compressors and their drives require a variety of auxiliary equipments to support their operation.

Compressor Maintenance

Compressors are complicated equipments and require frequent maintenance. They have heavy parts to handle during maintenance. They have frequently large size piping attached to it. All these facts must be considered during layout of compressor house.

Compressor Equipment Layout

Compressor equipment layout includes setting relative locations of various auxiliary equipments along with compressors, based on type of structure selected i.e. with shelter or without shelter. Check out following article on compressor equipment layout.

Compressor Piping Arrangement

There are many ways to develop a compressor layout, but certain aspects of these machines dictate how best to approach a design that optimizes operation, maintenance and safety while adhering to economic requirements.