Various types of steel containers are used to store liquids in a process plant. These storage tanks are located in areas commonly knows as off sites or tank farms. There two most important factors which govern the layout of such storage tank facilities, which are safety and economics.

Various inputs are required for safe and economic design of tank farms, such as :

- Local codes and regulations.

- Client Specifications.

- Topography of the area.

- Adjacent process plant.

- Neighboring commercial or residential property.

- Maintenance, operation and constructability.

|  | |

| There many shapes and sizes of storage tanks. Their choice depends on type of product …Read More.. | ||

Layout

When initially trying to establish a tank farm layout, the designer should consult NFPA codes and local codes and regulations.

Rules for spacing between tanks and all adjacent facilities usually can be found in the latest issue of the Industrial Risk Insurers “General Recommendation for Spacing’ pamphlet.

The NFPA will indicate what the designer should consider when grouping several tanks within a single dike or whether the tanks should be individually diked because of large capacities.

There is no simple answer to this layout problem. Each plant site is unique, with different products, tank capacities, fireprevention

requirements, terrain, and adjacent commercial or residential

property.

After the diking arrangement has been established, there are a few additional factors to plan for. The grade sloping away from the tanks to a sump must be determined; minor spills and rainwater may have to be pumped from the sump to a treating pond. Dike heights must also be established on the basis of inventories and available

real estate.

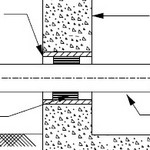

Building Dykes Around Obstruction

When a layout of a tank farm must be developed at an existing facility, unmovable objects or structures may obstruct the dike area. Following figure shows how a dike may be designed to accommodate obstructions.

Such designs are routine, but the spacing between the outside shell of the tank and the obstruction must meet NFPA or other governing regulations.

Dyke Wall Height Calculation

Generally dyke heights range from 3 ft to 6 ft (900mm to 1800mm) above internal grade. Minimum top dyke width required is 60 mm for operators to walk on them. A free board of 200 mm above calculated liquid level is generally required as per standards. Many project specifications specify dyke height of minimum 1 meter and maximum 2 meters.

Roads

Tanks shall be arranged in maximum of two rows so that all tanks can be approached by road around the dyke. Roads shall be on all four sides of dyke, and they shall be interconnected with roads of other dykes.

[google-square-ad]

Spacing Between Tanks

- Use table 3 of OISD-118 for separation distance between tanks and offsite facilities for large installations.

- Use table 4 of OISD-118 for separation distance betweens storage tanks in same dyke.

- Use table 5 of OISD-118 for separation distance betweens tanks and offsite facilities for smaller installations.

- Use table 6 of OISD-118 for separation distances for LPG Facilities.

Platforms, Ladders and Stairs

The maintenance vehicle ramp to have maximum grade of 15%. Do not use stairways for tanks of diameter less than 4.7m.

Storage Tanks Piping Layout

Piping layout of storage tanks depends on many factors such as :

- Type of tank.

- Tank Settlement

- Pump Location.

- Type of product to store etc.

Nozzle Layout

Special consideration shall be given as regards to spacing of nozzles while installing special item like hammer blind, MOV etc.

Pipes passing Through Dike

Where a pipe is routed through an earthen dike or firewall, the pipe shall be coated and wrapped. Where the firewall is concrete, the pipe shall be sleeved.

|  | |

| Most of the times, pumps are located outside the earthen dike, lines penetrating concrete dike …Read More.. | ||

Tank Farm Settlement

Piping shall be laid out to ensure sufficient flexibility to provide for settlement of tanks relative to pipe supports or anchors and differential settlement between tanks. If exceptionally high settlement is expected “dressers coupling” or “flexible ball joint” may be provided. Tank connections to be done after tank hydro testing.

Block Valves

All lines connected to nozzles on tanks below the maximum fill levels must be supplied with a steel block valve.

|  | |

| General Classification of Petroleum Products Petroleum products are classified according to their closed cup Flash Points …Read More.. | ||

|  | |

| The requirements given below are applicable to above ground LPG storage facilities. For mounded LPG storage, …Read More.. | ||

Storage Tanks within Process Unit

No other tankage except day tanks / process chemicals shall be provided within battery limits of any process unit. Process chemicals storage tanks should be provided with kerb wall of minimum 300-mm height. Hydrocarbons day tanks shall be provided with dyke as per OISD Standard.