Centrifugal pumps are the most widely used pumps in a chemical industry and refineries. They are used to transport wide variety of liquids and slurries like water, hydrocarbons, in-organic chemicals etc.

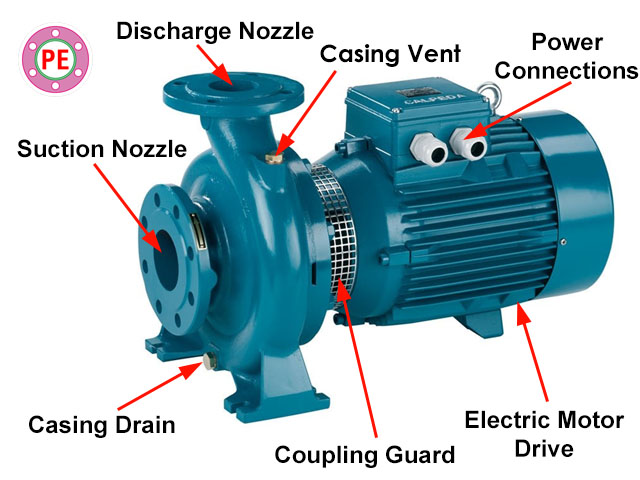

Following drawing shows an electric motor-driven horizontal pump that is familiar to plant layout designers.

Working

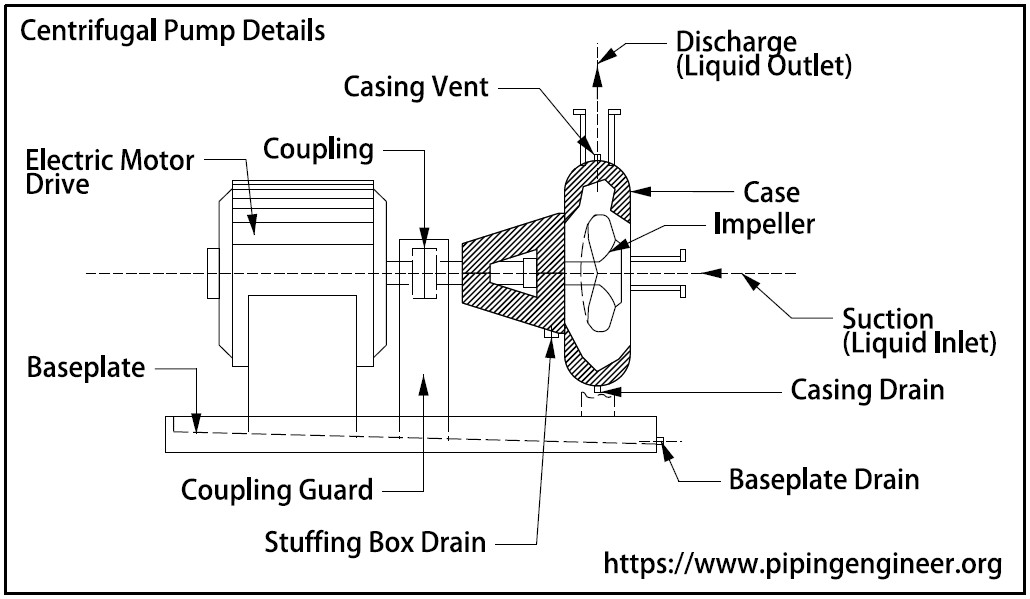

- The two primary piping connections are the suction and discharge nozzles (i.e., liquid inlet and outlet).

- The impeller within the pump case draws the liquid into the pump and sends it out at a high velocity.

- The impeller shaft is sealed with a stuffing box where the shaft exits the case to prevent the pump fluid from leaking.

- Drips from wearing seals are picked up in the stuffing box drain.

- The pump shaft is connected to the drive shaft by at coupling, which is enclosed within protective housing.

- Both pump and driver are mounted on a common base plate.

- Miscellaneous pump leaks that collect within the base plate during operation are drained through a connection at the front of the pump.

Pump Size and Configuration

Pump size and configuration vary for the following reasons:

- The commodity being pumped.

- The viscosity of the liquid.

- Capacity.

- Pressure.

- Temperature.

- Available head requirements.

- Physical limitations.

Layout Planning

During start of the project, initial pump piping layouts can be done with preliminary information about pump. The rotary equipment engineer supplies the plant layout designer with a catalog cut of the pump that most closely represents the one to be purchased.

In many cases, this data does not change significantly if the mechanical engineer has made the correct selection of catalog. Piping layouts are started early in the study phase; when the certified vendor drawings become available later in the project, minor adjustments are made as required.

Dimensions of nozzle locations or base-plate sizes may change slightly, but revisions to physical nozzle locations (i.e., from top to side or side to front) do not usually occur when the data is finalized.

Working closely with the equipment and process engineers acquaints the principal parties with the exact design conditions and minimizes rework.