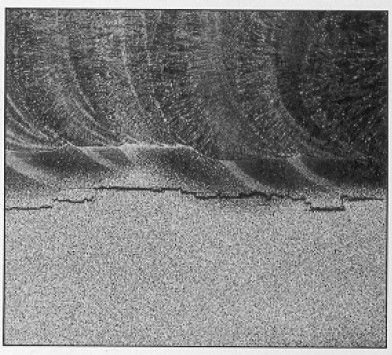

Lamellar tearing occurs only in rolled steel products (primarily plates) and its main distinguishing feature is that the cracking has a terraced appearance.

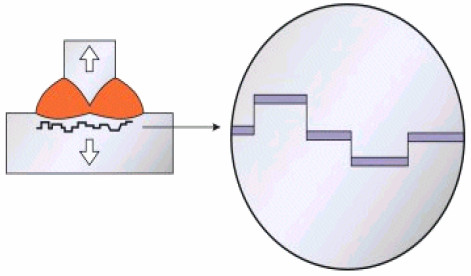

Cracking occurs in joints where:

- A thermal contraction strain occurs in the through-thickness direction of steel plate.

- Non-metallic inclusions are present as very thin platelets, with their principal planes parallel to the plate surface

Contraction strain imposed on the planar non-metallic inclusions results in progressive de-cohesion to form the roughly rectangular holes which are the horizontal parts of the cracking, parallel to the plate surface. With further strain, the vertical parts of the cracking are produced, generally by ductile shear cracking. These two stages create the terraced appearance of these cracks.

Two main options are available to control the problem in welded joints liable to lamellar tearing:

Use a clean steel with guaranteed through-thickness properties (Z grade) a combination of joint design, restraint control and welding sequence to minimise the risk of cracking.