It is essential to achieve highest quality of weld such that weld is as good as parent metal. Problems in welds can be classified as :

- Imperfection: Any deviation from the ideal weld.

- Defect: An unacceptable imperfection.

Classification of imperfections according to BS EN ISO 6520-1:

This standard classifies the geometric imperfections in the case of fusion welding, dividing them into six groups:

- Cracks

- Cavities

- Solid inclusions

- Lack of fusion and penetration

- Imperfect shape and dimension

- Miscellaneous imperfections

It is important that an imperfection is correctly identified thus allowing for the cause to be identified and actions taken to prevent further occurrence.

Cracks

Definition: An imperfection produced by a local rupture in the solid state, which may arise from the effect of cooling or stresses. Cracks are more significant than other types of imperfection, as their geometry produces a very large stress concentration at the crack tip, making them more likely to cause fracture.

Types of crack:

- Longitudinal

- Transverse

- Radiating (cracks radiating from a common point)

- Crater

- Branching(a group of connected cracks originating from a common crack)

These cracks can be situated in the:

- Weld metal

- HAZ

- Parent metal

Exception: Crater cracks are found only in the weld metal.

Depending on their nature, these cracks can be:

- Hot cracks (i.e. solidification cracks and liquation cracks).

- Precipitation induced cracks (ie reheat cracks, present in creep resisting steels)

- Cold cracks (i.e. hydrogen induced cracks).

- Lamellar tearing

Cavities

Cavities can be of various types as follows :

Gas Cavity : Formed by entrapped gas.

- Gas Pore

- Uniformly distributed porosity.

- Clustered (Localised Porosity).

- Linear porosity.

- Elongated Cavity.

- Worm-hole.

- Surface pore.

Shrinkage Cavity : Caused by shrinkage during solidification.

- Interdendritic Shrinkage.

- Crater pipe.

- Interdendritic micro-shrinkage

- Transgranular micro-shrinkage.

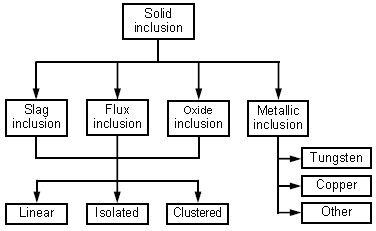

Solid Inclusions

- Slag Inclusion

- Flux Inclusion

- Oxide Inclusion

- Metallic Inclusion

Lack of fusion and penetration

Lack of fusion

Definition: Lack of union between the weld metal and the parent metal or between the successive layers of weld metal.

- Lack of side wall fusion.

- Lack of inter-run fusion.

- Lack of root fusion.

Lack of Penetration

- Incomplete penetration.

- Incomplete root penetration.

Imperfect Shape and Dimensions

- Undercut.

- Excess weld metal.

- Excess penetration.

- Overlap.

- Linear misalignment.

- Angular distortion.

- Incompletely filled groove.

- Irregular width.

- Root concavity.

- Burn through.

Miscellaneous Imperfections

- Stray arc.

- Spatter.

- Torn surface.

- Grinding mark.

- Chipping mark.

- Underflushing.

- Misalignment of opposite runs.

- Temper color.